INNOVATIVE PROCESSES, WIDE RANGE OF APPLICATIONS

Our full range of Carat Gold & Hallmarking brazing alloys complies with the international standard of solders permitted to be used. Fine spherical precious metal powders are the basic requirement for a wide variety of applications and innovative processes such as additive manufacturing (3D printing), MIM (Metal Injection Moulding), sintering techniques, thermal spray deposition and solder pastes & powders.

Additive Manufacturing

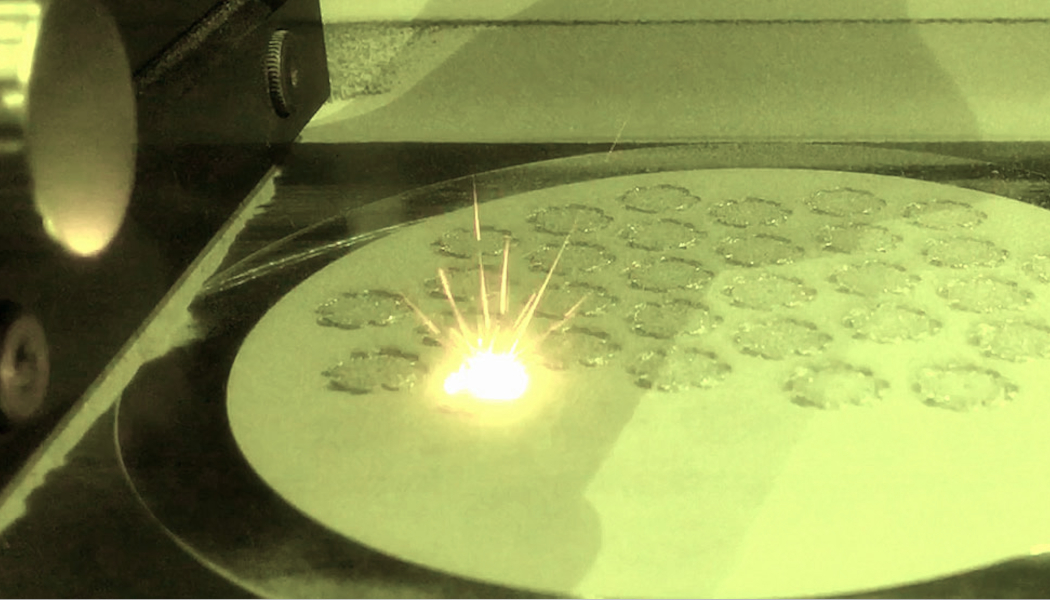

Precious metal powders are used in additive manufacturing because of their special characteristics. At C-HAFNER&HILDERBRAND we can provide them not only for the jewelry & watchmaking industry, but also for medical and others industrial applications.

Additive Manufacturing with precious metal powders mostly deals with powder bed technologies like even if direct energy deposition like laser-cladding can be of interest.

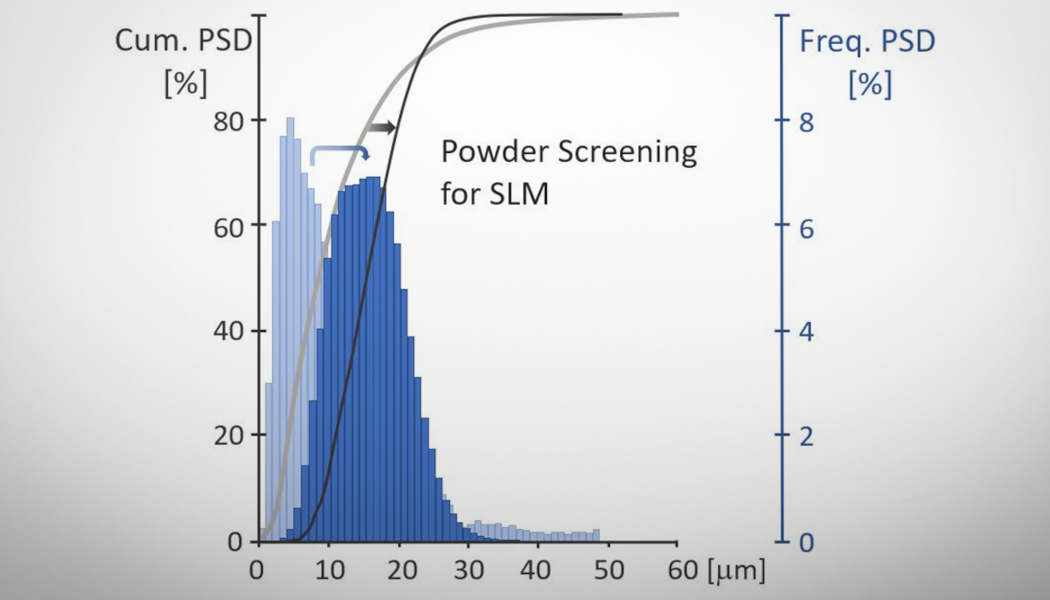

The desired PSD of powders for use in Additive Manufacturing by Selective Laser Melting is well correlated with the small particle size of powders atomized with the De Laval-based process. After screening, the yield for the PSD of the atomized batch is maximized leading to an easier qualification process of the precious metal alloy for SLM manufacturing ensuring the best combination with regard to density, surface roughness and feature size of 3D printed parts.

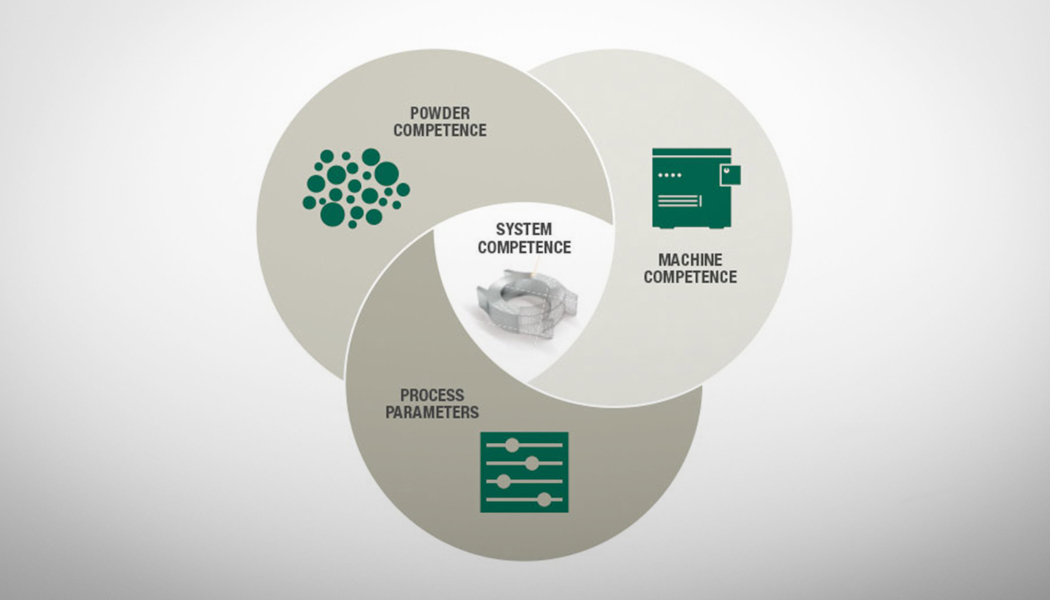

Our portfolio of high purity spherical precious metal powders include fine precious metals Au, Pd, Pt, Ag, Platinum group metal alloys (PGM), various colored carat gold alloys and customer-specific alloys adapted to each application. Because of the constraints of each application, the versatility of available SLM equipments on the market, the powder expertise is the only first pillar of the three central components of the selective laser melting process. Along with the metal powder, the machine expertise and process parameters to be applied require a perfect coordination one with each other.

This creates a system competence that makes possible to realize a generative production method for small industrial series. Our proven PlatinGold alloy for instance is an example of such qualified material for additive manufacturing by SLM.

Metal Powder Injection Molding (MIM)

Metal Injection Molding (MIM) is a powder manufacturing technology adapted for series production of small and precise precious metal parts of complex geometries. The fields of applications of MIM technology with precious metal alloys include medical technology, watchmaking and jewelry among others.

The elimination of machining process operations when compared to other technologies, the high material yield and low recycling costs are the advantages of MIM for serial production of precious metal parts.

The process is similar to plastic injection molding, with a feedstock (metal powder mixed with an organic binder) shaped using injection molding resulting in a so-called green part. This intermediate product is about 20% larger in dimensions than the final part. The binder is removed by chemical and thermal debinding giving a porous metal «brown part». The final part is then densified by sintering.

By mastering the atomization of various precious metal alloys including hard-to-process PGM alloys, C.HAFNER&HILDERBRAND can provide you with powders suitable for different feedstocks elaboration.

Brazing Pastes & Powders

HILDERBRAND® brazing pastes, also called solder pastes, are a homogenous mixture of brazing alloy powder with a binder and, in certain cases, with a flux, depending on the heating technique.

The alloy powder has the function of melting at the desired temperature, filling the gap by capillarity and assuring the joint strength after solidification. The binder assures easy and consistent dispensing and decomposes upon heating without leaving residues. A flux is added when the parts to be brazed are heavily oxidized or when heating is done in air.

All brazing pastes are custom made to ideally suit both the customer’s application needs and constraints with the following in terms of:

- Brazing Alloy composition and metal content

- Binders & Fluxes